描述

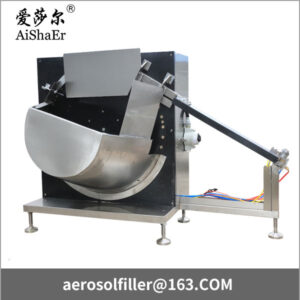

Automatic cassette gas valve inserting machine

Cassette valves are loaded and delivered to vibrating sorter by elevator, then sorted and fed to the guiding rail as process desire, the guiding rail is located above the rotary in-feeding head, at the end of the guiding rail, there is valve blocking unit, valves are held there waiting for next process.

Empty cans are transferred to the screw bar in-feeding unit of the machine, because of the specific pitch of the screw bar, neighbored cans are separated. Meanwhile, the rotary valve in-feeding head is working synchronously to deliver Cassette valve to theempty can, at the end of the screw bar there is sensor to detect can and relevant signal is sent out to the corresponding valve sucking head, which are distributed evenly to the rotary valve in-feeding head, to take the valve released from the valve blocking unit, when the can is coming to the valve sucking head, valve is inserted to the empty can automatically, valve sucking force is canceled and empty can with valve are sent out so that a single valve placing process cycle is fully ended, just repeat from beginning for a new cycle. When cans are transferring on the conveyor, both sides there are guiding fence or guiding belt.

Technical parameter:

| Overall size(mm) | 2040x960x1600 |

| Power(kw) | 3.0 |

| Air pressure(Mpa) | 0.6~1 |

| Air consumption (m3/min) | 0.8~1.0 |

| Speed (pcs/min) | 60~120 |

Features:

- Valve sorting machine supplies the valves for aerosol cans placing head automatically.

- The machine will stop by itself automatically to avoid cans with no valves are passed, if no valves coming.

- Equipped with a head to check and correct the position of the valve before crimping.

- Fast speed, high efficiency, saving manpower.