描述

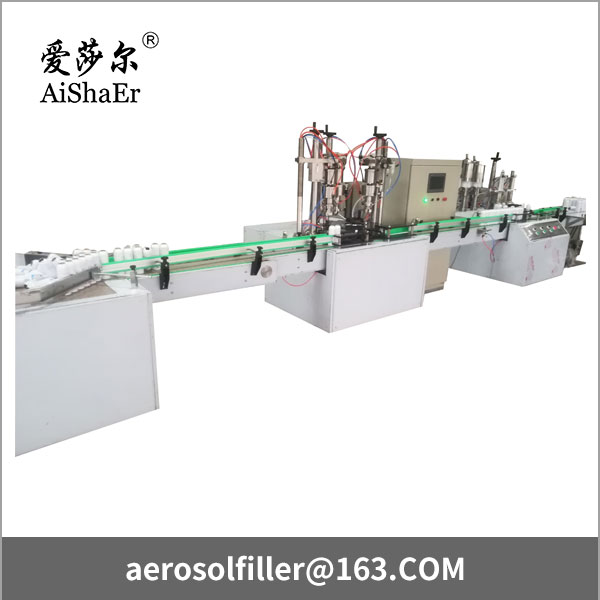

Full automatic bag-on-valve aerosol filling machine

Automatic bag on valve aerosol filling line includes cans arrange machine, capper, inflator, forced filling machine, belt conveyor, explosion proof motor, etc. The automatic bag on valve aerosol filler is equipped with labeler, weighing machine, water bath leakage tester, automatic pressure tester etc. for improving the automation of production line to achieve the goal of reducing staff.

Automatic bag on valve aerosol filling machine is to fill the compressed air into the can, seal the valve with the bag. The raw material is filled in the bag of the can which isolate the raw material from the can completely. The propellant is compressed air (purification) in place of the propyl butane liquefied gas, dimethyl ether, etc. which can solve the raw material leakage problem caused by the cans corrosion. When open the valve, the compressed air in the can compresses the bag to press the raw material out of the can. when the raw material is completely pressed out, the compressed air is still in the can, so it can be refilled again.

Application range:

It is used for filling air freshener, insecticide, disinfectant, household fire extinguishing agent, computer detergent, shaving foam agent.

Technical parameter:

| Applicable valve | 1inch(25.4mm) |

| Liquid filling volume(ml) | 10~300 |

| Liquid filling accuracy(%) | ≤±1 |

| Filling height(ml) | 70~330 |

| Inflation accuracy (Mpa) | ≤0.3 |

| Capacity(Can/hr) | 600~1800 |

Features:

- High speed, accurate filling quantity, good gas tightness, and the inflatable pressure can be adjusted to the required pressure.

- Adopts imported seal components.

- It is suitable for filling various valves.

- Adopt high-capacity two-way booster pump,

- Equipped with PLC+touch screen control